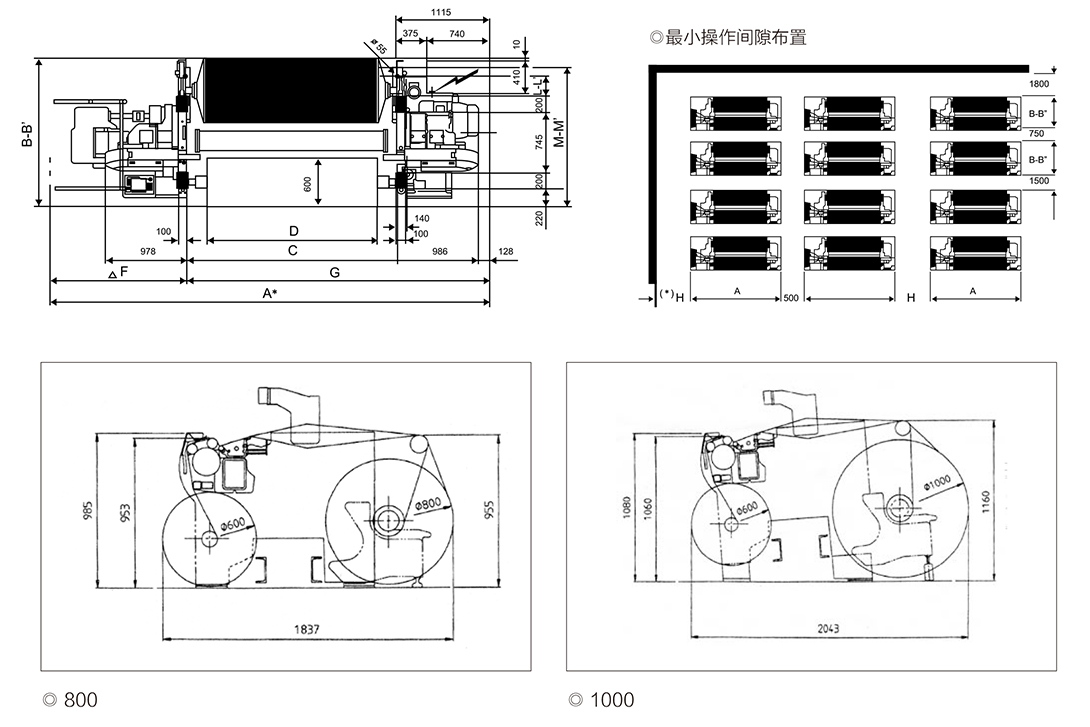

TT-828 Digital Hi-Speed Rapier Loom is a new generation mechanical & electric integrated loom researched and developed by our company. This machine applies a modular combination design concept and the high automatic numerical control technique, and is designed with compact structure, convenient and shortcut operation, minimal maintenance costs.

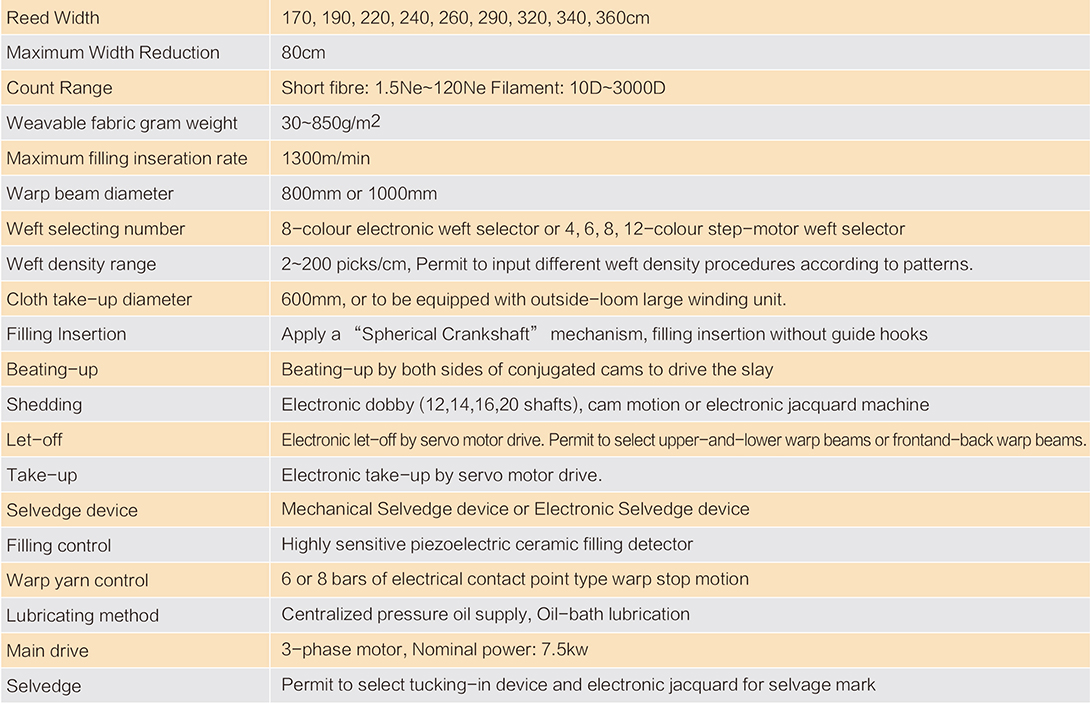

The designed running speed of the loom is 700 rpm. Its filling insertion rate is up to 1300m/min.Its reed width range covers 190~360 cm. Applicable to weave not only diverse garment & decorative fabrics, but also light, middlethick industrial fibre and glass fiber.

0575-86288859

Zhejiang Taitan Co. Ltd

Zhejiang Taitan Co. Ltd  Email

Email

浙公网安备 33062402000018号