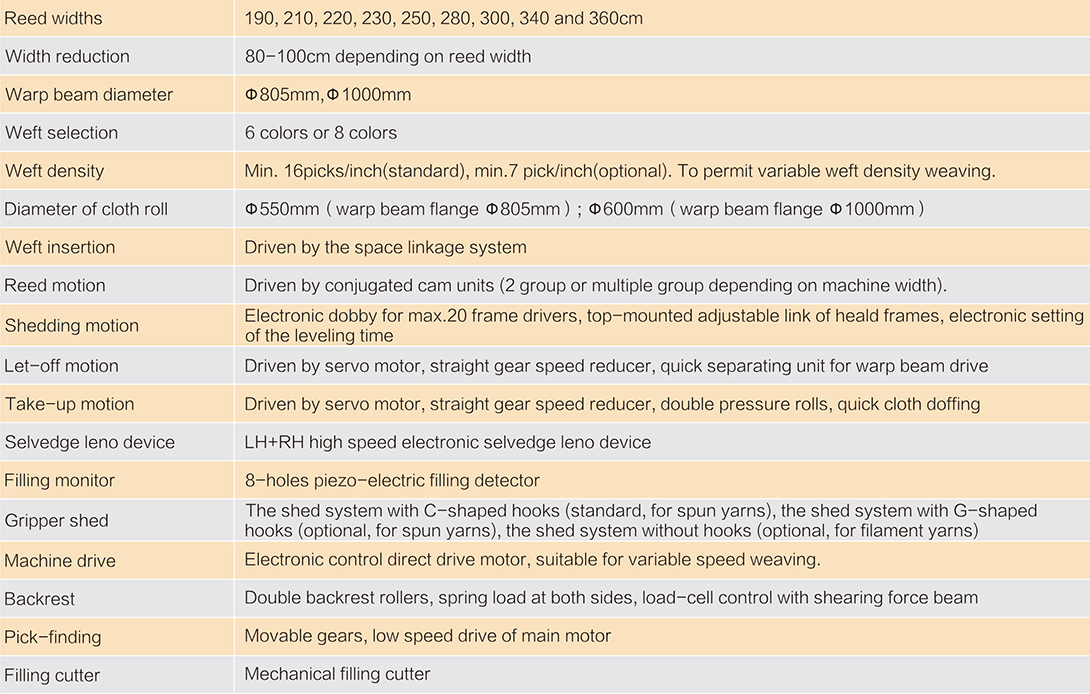

TT-858 direct drive intelligent rapier loom is a new generation of rapier loom developed by our company based on years of experience in design and production of rapier looms. It is the first direct drive motor developed and applied in China, with remarkable energy-saving effect. The structure of the whole machine is stable and reliable, without transmission belt, electromagnetic clutch, brake and other vulnerable components, which greatly reduces the maintenance time and consumption cost. It has the characteristics of high speed, high efficiency, low consumption and stability.

The maximum design speed of the machine is 750r P. M (t190) is suitable for weaving cotton and blended fibers, especially for weaving high-quality clothing fabrics, denim, yarn dyed fabrics and other fabrics.

The main transmission part of loom is directly driven by a motor with high starting torque which replaces to eliminating the electromagnetic clutch and brake system. The motor adjusts the output in real time based on load of loom. When the loom stops, the motor with stop in-phase so as to maximize energy saving. For optimal speed required for different fabric, just make some settings on the human-machine interface of loom. Main drive motor is directly lubricated and cooled through main oil circulating system, so there is no additional maintenance.

According to the different requirement of fabrics from users, the TT-858 has three kinds of interchangeable gripper shed systems:

The shed system C-shaped guide hooks, which can operate stably at a higher speed, is with better stability, small rapier head and small shed The shed system with G-shaped shed hook uses the slightly wider rapier tapes and the strengthening toothed wheels, Main consumable parts is cheap and bought easily in the market.

The shed system without guide hooks can provide maximum warp friendliness and get delicate fabrics. The system uses wide rapier tape in carbon fiber and toothed wheel in reinforced resin.The shed is made up of raceboard with flannelette.