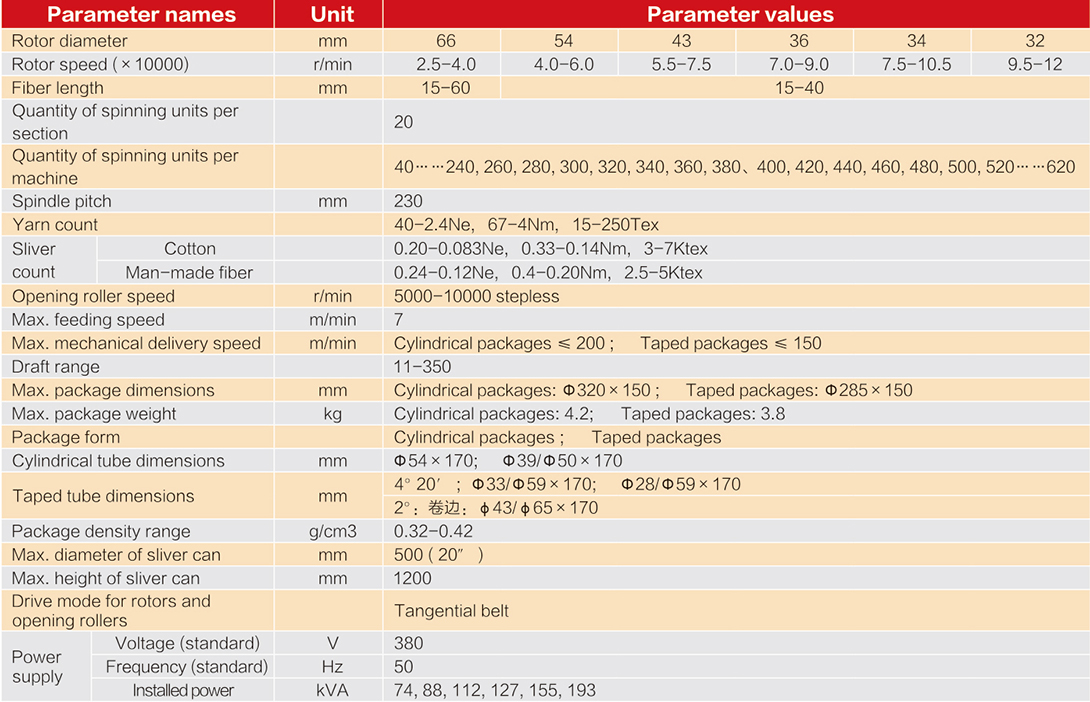

Double electrical box design, one machine can produce two varieties at the same time. Separate cotton feeding and electronic traverse mechanism using stepper motor.

Feed separately by step-motor, combined with professional computer software parameter design, independent segmentation control, improving the piecing quality and success rate.The negative pressure balloon compensator immediately stores the surplus yarn from the threading roller to ensure high quality packages and better unwinding in next process. Even when the piecing is made at the highest speed, the perfect package quality is ensured.The pneumatic automatic lifting arm device: automatically liftf after end-breakage, it is simple and reliable.The air pipe arrangement is simple and easy to maintain.The piecing operation is intelligently controlled, and the operator prepares the yarn end and puts it into the yarn drawing tube, close the spinning box and the piecing operation is automatically finished. With backspace, variable feeding, millisecond control, good piecing quality, simple operation, ensuring stable piecing success rate and quality.

Adopting the current international leading electronic traverse mechanism, The winding angle, the traversing difference period and the period change range can be adjusted freely through the display within the scope of the process to effectively reduce or eliminate the chrysanthemum core of the yarn package and ensure the normal unwinding of the package in next process. The electronic traverse mechanism is separately controlled at the left and right sides, so the yarns can be separately spun at both sides of machine. The cradle is with hydraulically damped device which ensures yarn forming and next unwinding, the maximum package diameter can reach 320mm, the weight of package is up to 4.5 kg Each : of the threading and winding shafts is driven by a separate motor, which has a simple structure and convenient adjustment of the spinning tension.